There was a time when people used to put-on hard labour to

break rocks. Rock drilling was too tough. With the advancement of technology, many innovative solutions came into existence. It can be said, “ A

new epoch started with the invention of rock drilling tools”. The rock drills

proved to be advantageous because rocks now can be easily cut down with ease.

No need to put any manual effort. Drilling is an essential activity for mining

industry right from exploration to every stage of production till end process

of mining, the upcoming of rock drills in the market gave a boost to the mining

industries.

Rock drills are essential not just for the mining industry,

but even it is needed for the construction projects. Generally, the rock drills/jackhammers

are used for concrete and asphalt. A jackhammer is the combination of hammer

& chisel. This particular tool is used to crumble the hard surfaces. A

major task of this equipment is to obliterate strong materials like asphalt,

rocks brick structures, solid and frozen ground. The mining and construction

industry is extremely dependent on these machines in the present era, due to

their light weight, high performance and ease of portability.

Nowadays, different manufacturing companies can be found

associated with the construction of pneumatic tools that are useful for the

construction and mining industry. Choosing a company producing high-grade

engineering work is in fact a very hectic job. To get information about the

best manufacturer for handheld jackhammer in India, this blog can act as a good source of

information.

Among many manufacturing companies in India, Mindrill has

established its niche as one of the principal manufacturers of handheld

pneumatic tools for mining & construction industry.

Mindrill & its Business

activities

Mindrill, today is recognized as a global supplier &

manufacturer of handheld pneumatic tools for mining and construction industries

in India. Founded in the year 1971, the company has been rendering its

outstanding services to customers worldwide. The factory and its corporate

office cover an area of 1,10000 square feet. With the support of 160 enthusiastic people dedicatedly, the company

has helped many entrepreneurs engaged in mining and construction business to

flourish. The organization has strong distribution centers in 25 countries

around the world. Besides this, the company is further planning to set-up its

distribution centers in countries like Australia, Canada, Kazakstan, Keyna,

Botswana, USA, Chile, Columbia, Russia, Tanzania.

Each and every product is developed after a thorough

research and quality testing. At Mindrill there are highly competent people

responsible for designing, production, testing and validation. The entire

business plan of action is divided into three categories-

●

Research

& development

●

Production

●

Sales

Mindrill supplies top-quality products to customers as per

demands & necessity & places customer satisfaction on its priority

list.

Check out the Products Manufactured By

Mindrill

Mindrill produces a wide array of products that can allow customers to

increase their productivity and generate more ROI (Return on Investment). The

Product portfolio includes various items like-

●

Rock

Drills

●

Sinker

Drills

●

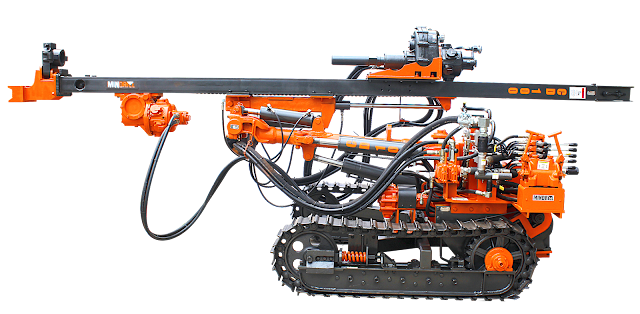

Crawler

Drills

●

Pneumatic

Drifters

●

Pneumatic

Breakers & Pics

●

Underground

Mining

Sinker Drill MH501L manufactured by Mindrill is in great demand in the

market. This pneumatic rock drill is a winner of its

class. It is can be easily used in tight spaces because of its low weight and

robust rifle bar rotation mechanism.

Sinker Drill MH501L Features &

Benefits

Sinker Drill MH501L is a light-weight machine and is used

for years in the small jobs and considered best fitted for mines with confined

operator spaces. This drill will allow miners to make a hole up to the depth of

1.5m with negligible air consumption. T-grip handles and its low-weight gives

the operator a comfortable experience while using it. Besides, the air flushing

system built in the drill rod restricts drill jamming by removing the drill

chips.

This specific part is characterized by low-pricing and

minimum running costs and one of the greatest advantages of this machine is, it

is used for small-scale exploration in confined regions and on tough terrain

because of modest air consumption and low weight. The key features of this

product are-

●

Low

air consumption

●

Ergonomic

vibration with Damped T-grip

●

Robust

Rifle bar Rotation mechanism

●

In-build

air flushing system

●

Ideal

for drilling in confined spaces

The length of this machine is 510mm while its weight is 19kg. For more information click on our product MH501L.