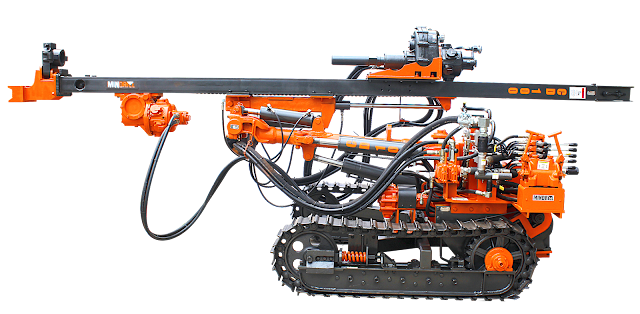

Drilling in challenging environments requires equipment that combines power, precision, and reliability. The Mindrill Yodha100 Crawler Drill has been engineered specifically to address the demands of rough and uneven terrains. Known for its robustness and versatility, the Yodha100 is the ideal choice for mining, construction, and infrastructure projects where conventional drills struggle. As a crawler drill for rough terrain, it ensures efficient drilling operations even in the toughest conditions.

Benefits of Using a Crawler Drilling Rig

Crawler drilling rigs are designed to navigate difficult landscapes while maintaining stability and performance. They offer several advantages over standard drilling equipment:

- Enhanced mobility: Tracks allow the rig to move over uneven and rocky surfaces without compromising balance.

- Durability in harsh conditions: Heavy-duty construction ensures the rig withstands the rigors of tough terrain.

- Operational efficiency: Continuous drilling in confined or uneven areas without frequent repositioning reduces downtime.

- Versatility: Crawler drills can perform a variety of drilling applications, from exploration to production.

These benefits make crawler drills an essential choice for projects requiring rough terrain drilling equipment.

Key Features of the Yodha100 Crawler Drill

The Yodha100 Crawler Drill stands out for its innovative design and superior performance. Key features include:

- Compact and Lightweight Design

Despite its heavy-duty capabilities, the Yodha100 is compact and portable, allowing easy maneuvering in confined spaces and difficult terrain.

2. Pneumatic Chain Feed System

Equipped with a pneumatic-driven chain feed, it delivers consistent drilling performance, even in hard rock formations.

With excellent hill-climbing capability and track oscillation, the Yodha100 maintains stability on slopes and uneven surfaces, making it ideal for rugged conditions.

4. Versatile Drilling Angles

The rig’s flexible feed boom arrangement allows drilling at vertical, horizontal, and inclined angles, ensuring access to hard-to-reach areas.

5. Durable Construction

Built with heavy-duty materials, the Yodha100 is designed to withstand continuous operations in harsh environments, reducing maintenance and downtime.

Applications of Mindrill Yodha100

The Mindrill Yodha100 is widely used in mining and civil construction projects. Its robust design and versatile capabilities allow it to drill efficiently in rocky terrains, steep slopes, and confined areas. By combining precision and strength, it enhances operational productivity and reduces project timelines.

Why Choose Mindrill Yodha100

Selecting the Yodha100 Crawler Drill ensures reliability, efficiency, and safety in your drilling operations. As a premium crawler drill for rough terrain, it is backed by Mindrill Systems & Solutions Pvt. Ltd., a trusted name in heavy-duty drilling equipment. The Yodha100 is not just a drill; it is a complete solution for challenging drilling environments.