Drilling through a hard rock surface is not

an easy job, it needs special rock

drilling tools and accessories for optimal performance. There is a wide range

of rock drilling tools and accessories, each designed for a specific application.

The rock drills come with certain features like lubrication, cooling system and

added drill bits.

High quality spares & accessories are

essential to get the maximum out of a rock drill. The spare parts need to be manufactured

with high quality raw material and machined to close tolerances so that it

performs well. There are many companies who are associated with production of

spare parts for rock breaking tools, but only a few deliver quality and

consistency like MINDRILL.

Mindrill

has been manufacturing handheld drills since 1971. Additionally, the company is

also known for its high quality spares & accessories including Taper Bits,

DTH Button Bits, Top Hammer Bits, Coupling Sleeve, Shank Adapter,and Split Sets.

The Taper Drill Bits manufactured by

Mindrill are a time tested and proven choice.

Mindrill rock

drill bits are produced with best raw materials. All rock drills, spares,

and accessories aremanufactured in aworld-class production facility in Domjur,

Howrah.

Key Features of MINDRILL Taper Button Bits:

·

High quality raw material

Mindrill has been working for esteemed

clients and serving customers globally for nearly 50 years. Today, it has its

distribution centers in more than 25 countries including USA,Canada, USA, Peru,

South Africa, Mexico, Brazil, Zambia & Zimbabwe.

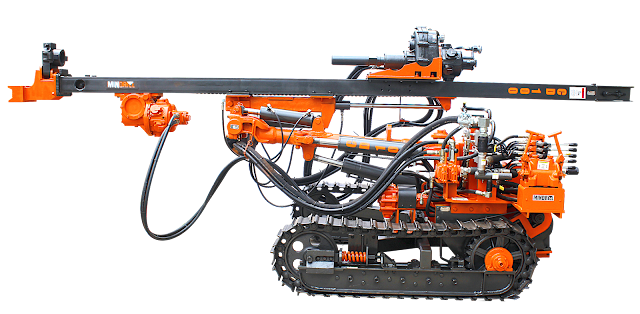

Mindrill is also known for its

high-performance handheld pneumatic drills. It manufactures a wide range of

rock drilling tools including Sinker Drills, Jackleg Drills, Stoper Drills,

Crawler Drills, Wagon Drills, DTH Hammers, Drill Bits, Pneumatic Drifters,

Pavement Breakers, Lubricators, Hydraulic Drifters, Spare Parts

&Accessories.